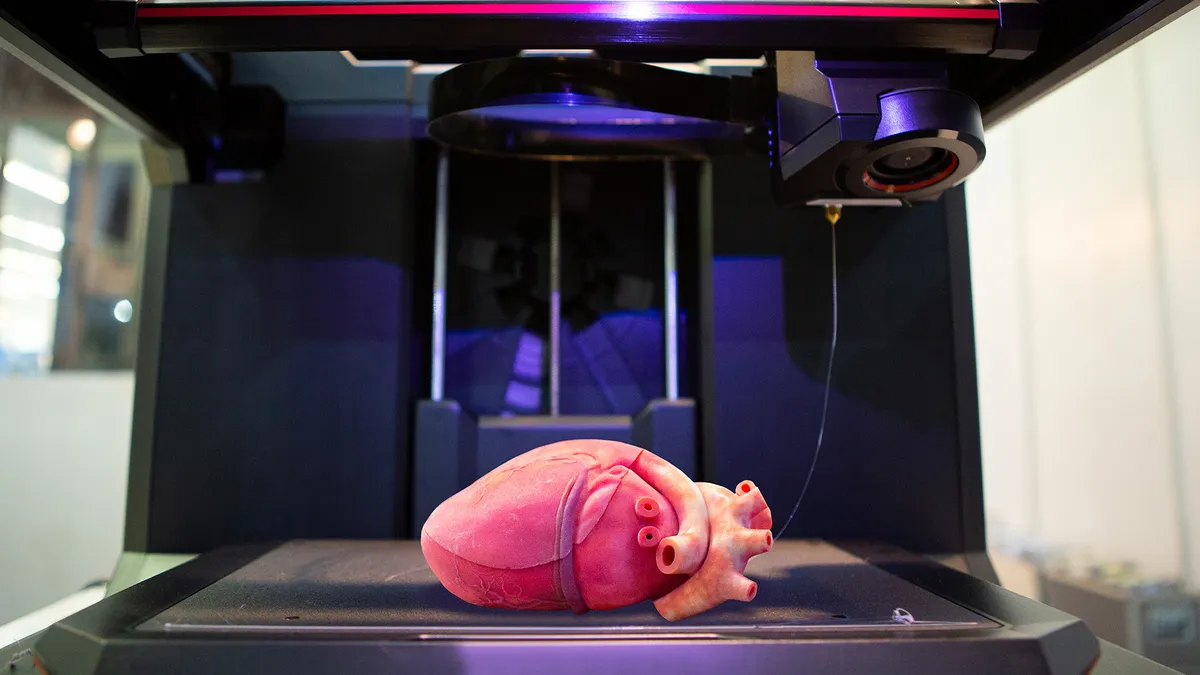

Three-dimensional bioprinting uses bio-inks mixed with living cells to print natural tissue-like structures. Currently, this technology can be applied to various research fields, including tissue engineering and drug development.

Now, the University of New South Wales, Sydney (UNSW Sydney) engineers have created a tiny, adaptable soft robotic arm that can 3D print biomaterial directly onto internal organs.

See Also

Published in Advanced Science on February 19, the research was conducted by Dr. Thanh Nho Do and his Ph.D. student, Mai Thanh Thai, in collaboration with other researchers from UNSW, including Scientia Professor Nigel Lovell, Dr. Hoang-Phuong Phan, and Associate Professor Jelena Rnjak-Kovacina.

The newly developed 3D bio-printed device, known as F3DB, can directly transfer multilayered biomaterials onto the surface of internal organs and tissues. They tested the F3DB inside an artificial colon and a pig's kidney.

"Existing 3D bioprinting techniques require biomaterials to be made outside the body and implanting that into a person would usually require large open-field open surgery which increases infection risks," Dr. Do, a senior lecturer at UNSW, said in a statement.

"Our flexible 3D bioprinter means biomaterials can be directly delivered into the target tissue or organs with a minimally invasive approach," he said

How does it work?

With a three-axis printing head, it directly mounts onto the tip of a soft robotic arm. The printing head functions very similarly to other desktop 3D printers since it is made of soft artificial muscles that allow it to move three dimensionally. Thanks to hydraulics, the soft robotic arm can be bent and twisted to any necessary length. Its stiffness may be precisely adjusted by utilizing various elastic fabric and tube types, as per the press release.